By: Keith Schneringer | April 30, 2020

Part one-of-three series analyzing the impact of COVID-19 on the Jan/San industry.

• Part One: Supply Chain Survey and COVID-19 Disruptions

• Part Two: The Effect of COVID-19 on Personal Protective Equipment (PPE) Supplies

• Part Three: The Ongoing Demand for Hand Sanitizers, Disinfectants and Toilet Paper – Oh My!

The topic of COVID-19 has dominated the news and collective psyche of the world1 for the last several months – and it may be the height of understatement to say that this intense focus has had a dramatic and oversized impact on many of the facets of our everyday lives which we may have previously taken for granted.

In addition to the implementation of social distancing measures2 which have kept us separated and unable to enjoy many of the daily opportunities for interpersonal interactions we are used to being able to have with our friends, families, and neighbors, the COVID-19 pandemic has also shined a very bright light on the global supply chain3 and our collective ability to be able to source and buy the products which are typically viewed as basic staples of our everyday lives, as well as those supplies which we can all agree are needed by those responsible for facilities maintenance in the buildings where we work, learn, heal, and relax in order to combat this new viral threat.

A Brief Overview of the Supply Chain

What is a “supply chain”, and what does it have to do with viral pathogens and facility maintenance supplies?

According to Investopedia, a supply chain4 is “a network between a company and its suppliers to produce and distribute a specific product to a final buyer…The supply chain also represents the steps it takes to get the product or service from its original state to the customer.”

In short, the supply chain is the process which is ultimately responsible for putting products on the shelves of grocery markets, big box stores, and wholesale distributors like WAXIE and others. In “normal” times, and prior to COVID-19, the global supply chain which has been developed over the course of the last several decades has shown itself to be extremely efficient at putting products where they need to be, when they need to be there, and at the lowest cost for all stakeholders.

Just-In-Time Delivery

Supply chain efficiencies have been improved by adopting just-in-time delivery. The practice of “just-in-time”5 delivery means that the individual components which will ultimately be combined to make a finished product arrive at the manufacturing plant shortly before they are needed in the assembly process. And as a result of this blend of meticulous forecasting, planning, and execution, products can be made and then purchased for lower prices, while simultaneously minimizing the expense and waste of holding excess inventory for manufacturers, wholesalers, and consumers alike.

Although there are always seasonal fluctuations and local market conditions to consider which may temporarily lead to some product scarcity, for the most part consumers in the U.S. have not been given a compelling reason in the recent past to have to think that hard about product availability. As a matter of fact, the average U.S. consumer has been conditioned by a plethora of recent purchasing experiences to expect to receive a product the next day, or at least very soon after placing an order for it.

However, COVID-19 has now given us a reason to think about the availability of products for consumers to purchase, the availability of products for wholesalers to sell, and the availability of raw material components for manufacturers to use to make the products which will ultimately go into the supply chain which serves us all.

Supply Chain Survey and COVID-19 Disruptions

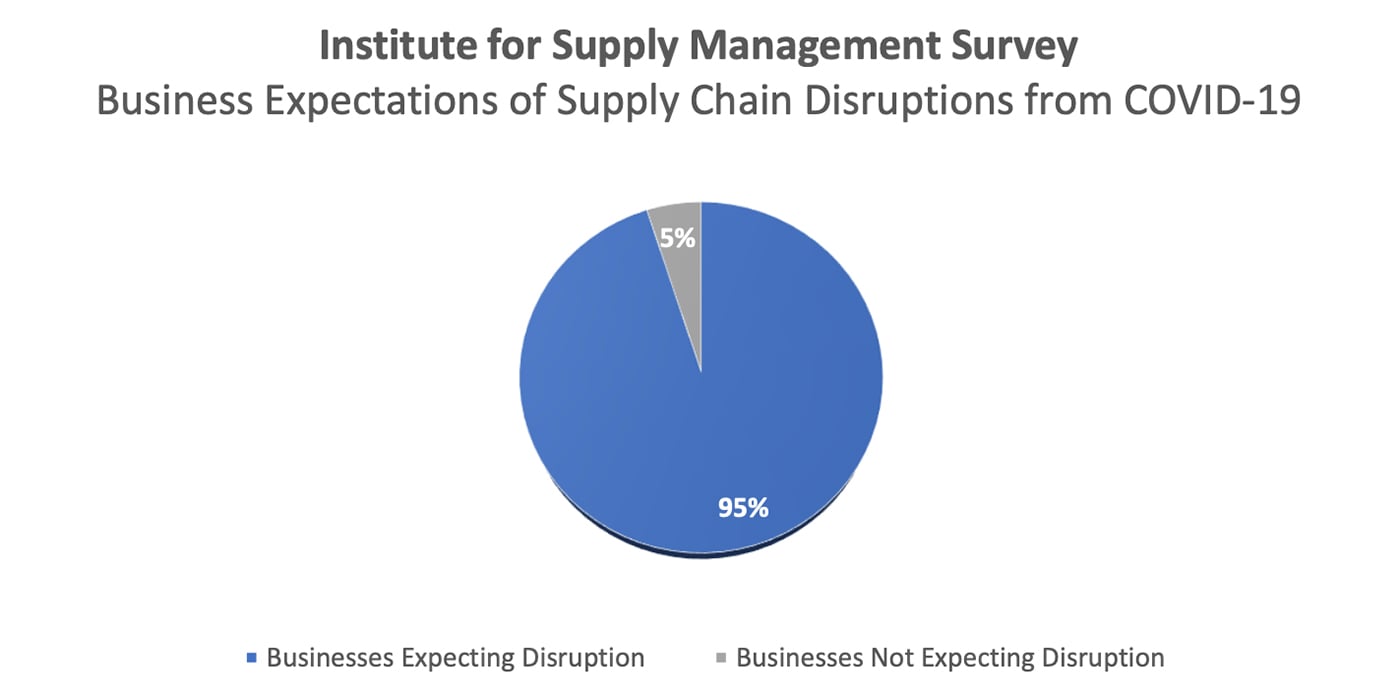

According to a recent survey of businesses and their supply chains by the Institute for Supply Management,6 95% of respondents are expecting to be impacted by supply chain disruptions as a result of COVID-19, with 86% of respondents seeing longer lead times for products sourced from China, 74% seeing longer lead times for products sourced from Europe, and 34-44% seeing longer lead times for products sourced from North America.

And while the global supply chain has shown resiliency and the ability to overcome specific short term traumatic events in the past,7 it is fair to say that the supply chain was not built to successfully accommodate the level of disruption which is occurring today as a result of COVID-19.

Government lockdowns of countries, unavailable and/or sick factory workers, factory shutdowns, international border closings, decreased international shipments via ocean and air, immediate and dramatically huge surges in demand for products across many disparate product categories, international competition for finite product resources, panic buying, and product hoarding are all contributing factors to create a situation where product shortages within the supply chain can be expected to occur.

And since the supply chain has become so global, a worldwide event like COVID-19 is proving to have far-reaching impacts on product availability throughout the supply chain.

Sources:

- Psychology Today website article, Media, Fear, and the Coronavirus Outbreak, March 3, 2020 https://www.psychologytoday.com/us/blog/the-runaway-mind/202003/media-fear-and-the-coronavirus-outbreak

- Centers for Disease Control and Prevention (CDC) website, Social Distancing, Quarantine, and Isolation, reviewed April 4, 2020 https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/social-distancing.html

- Investor’s Business Daily website article, Coronavirus Business Closures Unmask Global Supply Chain Defects, April 17, 2020 https://www.investors.com/news/technology/supply-chain-management-flaws-ripped-open-coronavirus-business-closures/

- Investopedia website, Supply Chain, updated February 10, 2020 https://www.investopedia.com/terms/s/supplychain.asp

- Marketplace website article, “Just-In-Time” Manufacturing Model Challenged by COVID-19, February 27, 2020 https://www.marketplace.org/2020/02/27/justintime-manufacturing-model-challenged-coronavirus/

- Institute for Supply Management website, Coronavirus Resource Center, COVID-19 Global Supply Chain Disruptions Continue, April 14, 2020 https://weareism.org/coronavirus-ism.html and https://www.instituteforsupplymanagement.org/news/NewsRoomDetail.cfm

- World Economic Forum website article, What Past Disruptions Can Teach Us About Reviving Supply Chains After COVID-19, March 27, 2020 https://www.weforum.org/agenda/2020/03/covid-19-coronavirus-lessons-past-supply-chain-disruptions/