Truth in Packaging—How 5 Measurements Can Save you Money

While it might seem like you're getting a good deal with off-brand trash can liners, deceptive labeling practices often fly under the radar. Between broken or ill-fitting bags and inaccurate bag counts, it’s easy to spend more than you should.

While it might seem like you're getting a good deal with off-brand trash can liners, deceptive labeling practices often fly under the radar. Between broken or ill-fitting bags and inaccurate bag counts, it’s easy to spend more than you should.

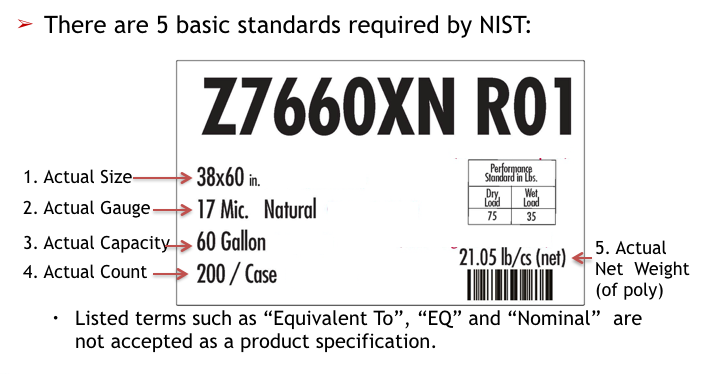

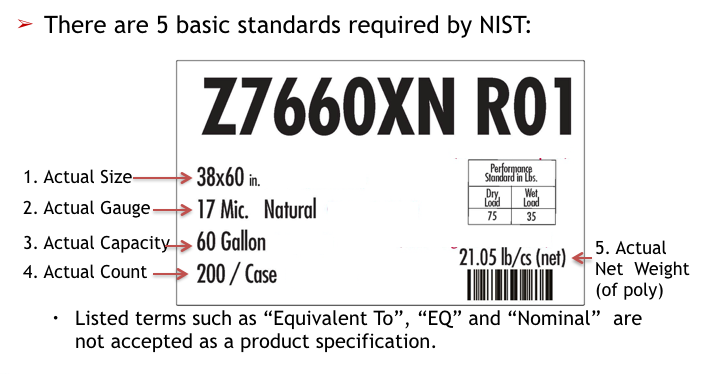

To make sure you're getting the best value, this post will go through the five things every label must include, per the National Institute of Standards and Technology (NIST). Then we'll show you a formula that ensures the label you're reading is accurate.

1. Size

Most trash can liner sizes are designated by two numbers—width and length, e.g. 33x40. Trash bag liners with gusset seals (which are less common) are measured in three dimensions. The third dimension is depth.

2. Gauge

Gauge measures thickness of the can liner material. Gauge measurements will be expressed in terms of mil or microns.

- One mil is equal to a thousandth of an inch. Can liners range between .35 and 4.0 mil.

- Microns are a metric unit of measurement. 25.4 microns are equal to one mil. The units used to measure gauge vary depending on the plastic.

The two main types of plastic are Linear Low Density (LLD) and High Density (Hi-D). Note which material your liner is made of so you can make the correct calculations to ensure label accuracy. The gauge of a can liner is helpful in determining the strength of the bag. But it is not the only thing that matters. Advanced polymers make even thin plastic quite durable.

3. Capacity

Capacity is measured in gallons for trash can liners. It's important to note, though, that 'capacity' does not refer to how much weight the bag can handle. That depends on other factors like the quality of plastic, the seal, and the gauge.

4. Case Pack

Case pack is the number of trash can liners you get per case. Many trash can liners come with more than 100 liners per case, so counting each case wouldn’t be practical. Luckily, you can ensure truthfulness in packaging labels with a simple calculation. That brings us to the last measurement that NIST requires.

5. Case Weight

Case weight is simply the weight of the case. You can use case weight to determine whether everything on the label adds up or not. Just plug in the measurements for length, width, gauge, and case pack into the appropriate formula below.

Be on the lookout for these five measurements. Quality can liners help keep your facility cleaner, healthier, greener... and safer.

Can Liner Measurement Calculation

Linear Low-Density Case Weight Formula

Length x Width x Gauge (in mils) ÷ 15 ÷ 1000 x bags per case = net lbs. per case (approximate)

High-Density Case Weight Formula

Length x Width x Gauge (in microns) ÷ 14.5 ÷ 25.4 ÷ 1000 x bags per case = net lbs. per case (approximate)

Heritage Bag has provided this great calculator to check competitors' labels to ensure truth behind the label.

While it might seem like you're getting a good deal with off-brand trash can liners, deceptive labeling practices often fly under the radar. Between broken or ill-fitting bags and inaccurate bag counts, it’s easy to spend more than you should.

While it might seem like you're getting a good deal with off-brand trash can liners, deceptive labeling practices often fly under the radar. Between broken or ill-fitting bags and inaccurate bag counts, it’s easy to spend more than you should.